MBR STP Manufacturer

KWTPL is the best Leading MBR STP Manufacturer and supplier in India that is appreciated by the clients for high quality standards. Our expertise lies in designing and implementing prefabricated hybrid sewage and wastewater treatment plants using both aerobic and anaerobic processes like SBR, FBBR, and MBR. The key advantages of our systems include their compactness, odor-free operation, low power consumption, ease of maintenance, quick installation, minimal civil work requirements, reduced operational noise, adaptability for modifications, and minimal sludge generation.

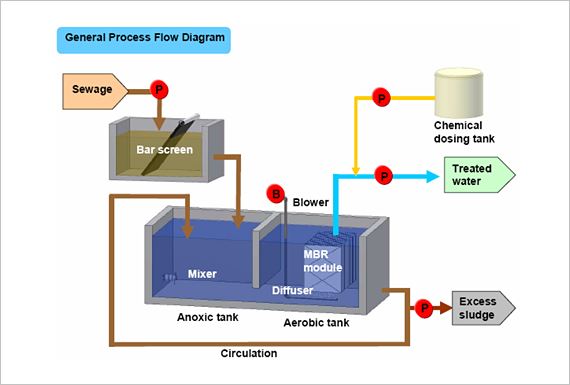

This innovative technology merges membrane processes like microfiltration, nanofiltration, and ultrafiltration with the ASP (Activated Sludge Process) for biological wastewater treatment. It represents a significant leap forward in wastewater management, specifically addressing the limitations inherent in conventional ASP systems. These drawbacks include the spatial demands of secondary clarifiers, issues with liquid-solid separation, excessive sludge generation, and the struggles in eliminating recalcitrant substances.

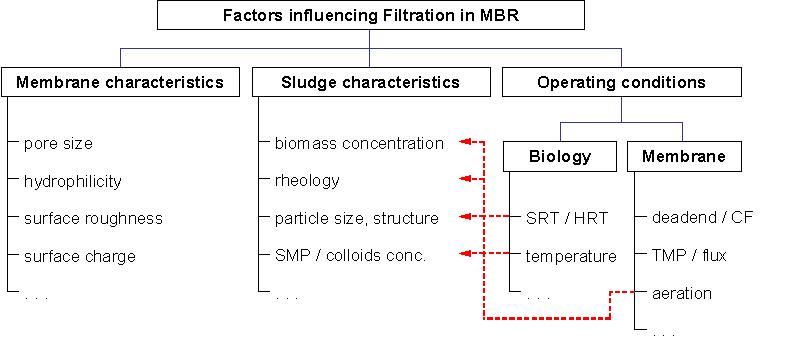

A standout feature is its ability to sustain higher levels of mixed liquor suspended solids (MLSS) compared to traditional aeration tanks, effectively reducing the treatment plant's footprint. However, it's essential to note that while diffused aeration remains integral, the membrane technology itself varies among vendors, each offering distinct throughputs per membrane module. Moreover, vendors may advocate different membrane shapes such as flat sheet, cross-flow, or dead-end flow, posing a challenge in establishing uniform design criteria across the industry.

MBR STP is available in two configuration

1.Internal/ Submerged- In this configuration the filtration element is installed in the main bioreactor vessel or in any separate tank. The membrane can be a combination of tubular and flat sheet and an online backwash system ca be incorporated which can reduce membrane surface fouling umping membrane permeate back through the membrane. 2. External/Side stream- In this configuration filtration element are installed externally to the reactor. Membrane modules are arranged in series through which biomass is pumped to the bioreactor or bank modules.

Major Consideration in MBR-

Membrane Fouling & Fouling Control- The major drawback of this system is of membrane fouling due to the deposition of insoluble and particulate materials onto and into the membrane. Due to this membrane performance inevitably decreases with filtration time. It affects the system performance & operating cost of plant

MBR STP Advantages

-

High quality effluent for reuse without separate nutrient removal and fine filtration.

-

Compact system reduces plant footprint by 25-40% compared to a conventional STP

-

These membranes are stated to be durable to ensure reliability and long membrane life, and low membrane replacement frequency.

-

The modular system is expandable.

-

Higher stability to organic shocks /upsets due to higher MLSS concentration.

-

The process operates under low suction, the ideal filtration method for small to large-scale membrane facilities, hence low power consumption.

-

Automated system makes the process operations easier to operate.

MBR STP Disadvantages

-

Each vendor advocates his own criteria for the membranes and their types which makes it difficult to bring about a common and validated design criterion.

-

It is not possible to cannibalize the system between different manufacturers.

-

High reliance on energy input in the absence of bio methanation.

-

Patented process technology and decanters defying local cannibalization.

-

Detailed evaluation of existing plants required either by IITs, CPCB or NEERI.