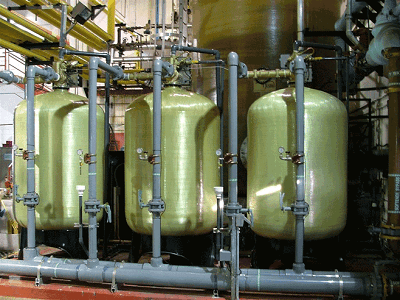

Demineralization Plant/DM Plant-MB Plant

DM Plant completely fill our need for demineralized water completely free of dissolved minerals. Demineralization is the process of removing mineral salts from water using an ion exchange process. We have with us extensive experience in making available precision engineered and functioning Demineralization Plant. These plants come backed with latest ion exchange technology that helps these plants to effectively remove salts including cations and anions from water which as soluble chemical compounds become ionized when dissolved in water.

Product Details

Demineralization plants available in form of automatic two-tank plants or as mixed-bed plants.

These are frequently used where there are stringent needs of low content of salt and silica in water.

Demineralization plants specially designed to provide low-cost supply of de-ionized water that is typically less than 10 micro-siemens.

Chemical resistant valves used on vessels that control service and regeneration flows.

These plants make use of commercially available hydrochloric acid and sodium hydroxide for regenerating resins when required.

Application Areas

Demineralizers are used in demineralization plants and systems for various commercial, residential and industrial applications.

FAQs – Demineralization Plant

Q1. What is a Demineralization Plant?

Ans. The DM Plant fully satisfies our demand for demineralized water that is devoid of dissolved minerals. Demineralization is an ion exchange procedure used to remove mineral salts from water. We have a wealth of experience in providing precisely constructed and operational demineralization plants. These plants are equipped with the most recent ion exchange technology, which enables them to efficiently remove salts from water, including cations and anions, which are soluble chemical compounds that become ionised when dissolved in water.

Q2. What is demineralized water used for?

Ans. In many industries, the high-purity water from a demineralization plant is typically used as feed water for high pressure boilers, as wash water in processes for making computer chips and other microelectronics, as pharmaceutical process water, and in any other process where high-purity water is necessary. In the production of chemicals, fertilisers, food goods like soft drinks, vehicles for washing parts, textiles, etc., DM water is utilised as process water.

Q3. Why are there numerous types of resins used in demineralization plants?

Ans. The kind of resins used and chosen relies on a variety of factors: Requirement for treated water quality - If silica removal is not necessary, INDION 850 weak base anion resin is typically used as the anion exchange resin in two-bed DM plants. The INDION N-IP strong base Type-2 resin is recommended if a silica concentration of 1.0 ppm can be tolerated. When silica-free water is desired, INDION FF-IP strong base Type-1 anion resin is charged into the anion exchanger.

- Presence of organic foulants - Microporous resins, such as INDION 810-Type 1 strong base resin, are better suitable for the application than INDION FF-IP in situations where water has a high level of organic foulants, such as humic and fulvic acids present in natural surface waters.

- Taking into account regenerant chemical use to minimise running costs: In large plants, INDION 850 resin, which is very effective at removing strong acids like HCl and H2SO4 from water with little need for alkali for regeneration, is combined with INDION FF-IP strong base resin, which works best at removing weak acids like carbon dioxide and silica, to reduce regenerant chemical consumption.

Q4. Why is DM water used in power plant?

Ans. Demineralized water is frequently used for steam production and boiler feed water in the power sector. High-pressure boilers are needed for steam generators that power turbines because they can remove as many pollutants from the feed water as possible.

Q5. How do you regenerate DM water plants?

Ans. Cation and anion exchange units are the first part of a DM plant, followed by a mixed bed unit. Sulfuric acid is typically used to replenish cation exchange units. Hydrochloric acid is used in a few industries as a regenerant. Sodium hydroxide is used to renew the anion exchange units.

Q6. What is the Demineralization Process?

Ans. Demineralization The process of treating water is physical. Specially created ion exchange resins help to exchange the mineral salts in water. Anion exchange and cation exchange resins are the two different types of resins. The former resins discharge hydroxyl ions, which are typically ions with a negative charge. The hydrogen ions, which are typically positively charged ions, are released by the cation resins.