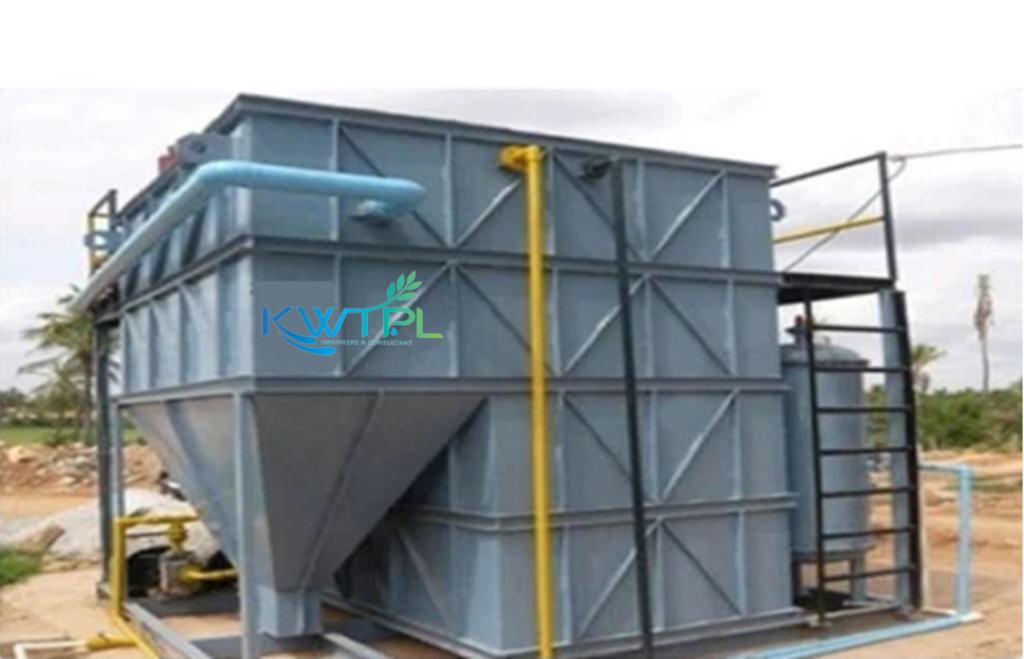

Packaged Sewage Treatment Plant

A Packaged Sewage Treatment Plant (PSTP) is a pre-engineered and factory-built system designed for the treatment of wastewater or sewage from residential, commercial, or industrial sources. These plants are also known as prefabricated or containerized sewage treatment plants.

Key Features and Components of Packaged Sewage Treatment Plant:

Containerized Design:

The entire sewage treatment process is housed in a compact, modular container or structure, making it easy to transport, install, and maintain.

Treatment Processes:

Packaged Sewage Treatment Plant generally incorporate various treatment processes to remove impurities and contaminants from wastewater. Common processes include:

- Primary Treatment: Removal of large solids through processes like screening and sedimentation.

- Secondary Treatment: Biological treatment to break down organic matter using microorganisms.

- Tertiary Treatment: Additional processes to further refine the treated water, removing remaining impurities

Biological Treatment Units:

These units often consist of aerobic or anaerobic reactors where microorganisms break down organic pollutants in the wastewater.

Clarifiers:

Clarification units help separate solid particles from the treated water through settling, allowing the clean water to be separated from the sludge.

Disinfection Systems:

After the biological treatment, disinfection processes (such as chlorination or UV irradiation) may be employed to kill or inactivate the remaining pathogens in the treated water.

Control Systems:

Automated control systems monitor and manage the various treatment processes, ensuring optimal performance and efficiency.

Monitoring and Instrumentation:

Packaged plants equippe with sensors and instruments to monitor parameters such as pH, dissolved oxygen, and turbidity, providing real-time data for process control.

Odor Control Systems:

Depending on the design and location, odor control systems integrate to manage any unpleasant smells associated with the treatment process.

Energy-Efficiency Features:

Some advanced packaged treatment plants may incorporate energy-efficient technologies, such as variable-speed drives and energy recovery systems.

Compliance:

Packaged Sewage Treatment Plants are design to meet local and national regulatory standards for treated water quality and environmental discharge

Process of Packaged Sewage Treatment Plant

1. Preliminary Treatment

The influent sewage water passes through a bar screen to remove all the large objects like cans, rags, sticks, plastic packets, etc. which carry in the sewage stream.

2. Secondary Treatment

a. Anaerobic Zone-

In the first stage of PSTP, the solids in raw sewage settle while allowing the scum to float on the surface, and the settled sludge is stabilize by anaerobic digestion.

b. Anoxic Zone-

When the wastewater streams enter the anoxic zone, denitrification occurs by returning the activated sludge from the final sedimentation zone to the anoxic zone; the level of dissolved oxygen in the anoxic zone is approximately 0.2 to 0.5 mg/l. As a result of the breakdown of existing nitrates by anoxic microbes, inert nitrogen gas is release into the atmosphere.

c. Aeration Zone-

In the aeration zone, the sewage from the solid separation zone flows. In the aeration zone, air is diffused by air blowers, which stimulates the growth of bacteria cultures in and around the floating plastic media. A large surface area is provided by the MBBR media, allowing microorganisms to grow more readily.

d. Sedimentation Zone-

As part of the treatment process, organic waste settles in the sedimentation zone. To ensure that the effluent meets the specified sewage parameters, the settled waste at the bottom of the tank is pumped back to the anoxic zone as a return sludge.

3. Tertiary Treatment System:

A pressure sand filter and an activated carbon filter remove suspended solids (TSS), color, and odour from the secondary treated sewage, which is then disinfected with sodium hypochlorite.

Packaged Sewage Treatment Plant Advantages:

Packaged systems with pre-assembled, skid-mounted, and factory-tested parts require less installation time and reduce construction costs onsite.

- compact designs for easy integration into existing facilities

- completed engineering packages with quick delivery

- Comprehensive cleaning capabilities for peak system performance

- Easy operation and maintenance require minimal operator supervision.

APPLICATION AND USES

- Residential and Commercial Complex

- Public Garden and National Park

- Hotel & Resorts

- Restaurants

- Industries

- Institutions

- Hospitals

- Temples

- Government Offices

- Labour Quarters

- Township

- Hostels